Elasto Proxy makes rubber products that support data center fire protection.

March 31st is World Backup Day, a global effort to encourage businesses, individuals, and organizations to protect their digital data by creating and maintaining backups. Storing backups off-site can help with recovering from cyberattacks or natural disasters, but what if a fire struck your facility? You’d still have your data, but would your computers and other IT assets survive?

Data centers are at risk of fire because of their dense concentration of electrical equipment. Although these fires are rare, they happen. That’s why it’s important to take a multi-faceted approach to safety. In addition to reviewing fire suppression and mitigation plans, operators need to harden their facilities against fire damage and update their disaster recovery strategies.

As part of these efforts, facilities managers can require data center construction companies to install fire-resistant gaskets for doors, panels, and enclosures. Elasto Proxy makes fire retardant gaskets from UL 94 HB EPDM sponge rubber. This flame-rated material can also resist water, heat, and steam. In addition, it resists compression set and is cost-effective and easy-to-install.

Keep reading to learn more and contact Elasto Proxy to discuss your data center project.

UL 94 Flame Ratings and Data Center Fire Protection

Maybe you’ve heard of the UL 94 flammability standard from Underwriters Laboratories (UL). But did you know there’s a difference between UL 94 V0, which is a vertical burn rating, and UL 94 HB, which is a horizontal burn rating? There are also different vertical burn ratings like UL 94 V1 and V2. In addition, materials that are UL certified vs. UL compliant are not the same.

For data center builders and operators, it’s important to choose rubber materials with the right UL 94 rating. Because most fire suppression systems are water-based, it’s also essential to determine if a rubber product can withstand water, heat, and steam. High-temperature resistance is also required because data center electronics generate significant amounts of heat during normal operation.

Impact resistance is an additional requirement. For example, consider the rubber gaskets that are used between metal data center panels. They need to be soft enough to compress, fill the gap between two surfaces, and form a seal. Yet, the rubber must also withstand permanent deformation. If a data center gasket becomes crushed from compressive stresses, seal failure may occur.

From Material Selection to Gasket Installation

In addition, data center gaskets need the proper size and shape. Height and length are key measurements, but so is the width of the gap that the gasket is designed to fill. Along with these technical specifications, data center builders and operators need to think about gasket costs, order quantities, lead times, and ease-of-installation. There are several challenges to consider.

Because fire-resistant rubber is a specialty compound, it’s more expensive than a commodity material. Plus, the minimum order quantities (MOQs) can be higher than what data center builders and operators expect, and tooling charges may apply. The tools, or dies, that are used to extrude lengths of rubber take time to build, and the extrusion process itself carries lead times.

Cost is a key consideration, but the data center industry also wants rubber gaskets that are easy-to-install. For example, taped gaskets allow an installer to peel back a protective liner and stick the gasket in place. Gasket tapes can provide either temporary or permanent bonding, but the ones that are used in data centers need to meet the same UL 94 rating as the gasketing material itself.

Data Center Fire Protection Case Study

Finding the right fire-retardant gaskets might seem challenging, but some data centers are already using rubber products that address all their business and technical concerns. For example, when a leading search engine needed to build more data centers, the operator asked the builder to source fire-resistant gaskets from Elasto Proxy.

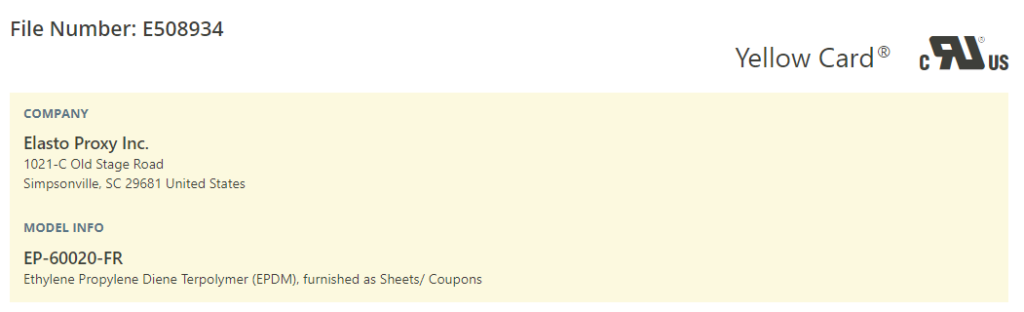

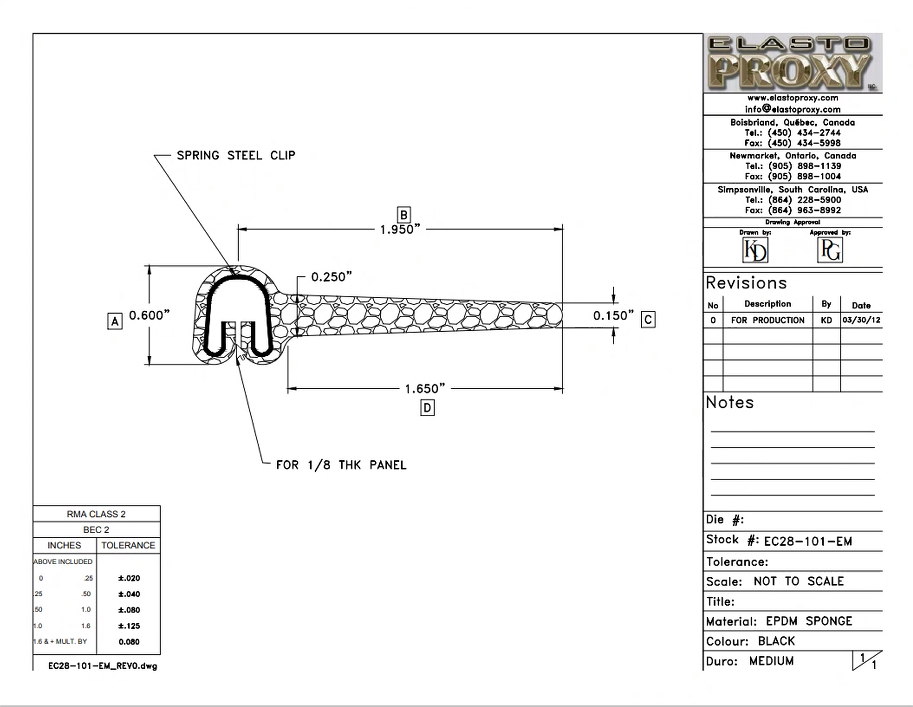

The compound that the data center specified was a UL 94 HB EPDM sponge rubber with a spring steel clip for impact resistance. This black EPDM has a UL Yellow Card, a product information document that lists safety and performance properties, and which proves that the material meets the applicable UL standard. This gasket material also provides heat, steam, and water resistance.

Although it contains a steel clip, the rubber still has a durometer that supports proper compression. Products made of this material are designed to fit a 0.125-in (3.175 mm) gap between panels, and they support the use of fire-resistant adhesive tape. Because the data center chose an existing product, no special tooling was required – and the MOQ was lower than for a custom extrusion.

Ask Elasto Proxy About UL 94 Gaskets for Data Center Fire Protection

As demand for data centers continues to grow, builders and operators need to choose quality materials to protect their investments. UL 94 HB EPDM sponge rubber gaskets won’t prevent events such as battery fires or electrical arcing from happening, but they can help to mitigate the potentially catastrophic effects in the event of a data center fire.

Are you ready to learn more? Ask Elasto Proxy for UL 94 HB EPDM sponge rubber and talk to our team about materials that we now offer for EMI shielding. They include silicones that have a UL 94 V0 flame rating and are available in 40-durometer or 60-durometer. We can water jet cut them for you at our headquarters near Montreal, Canada, or in Simpsonville, South Carolina (USA).